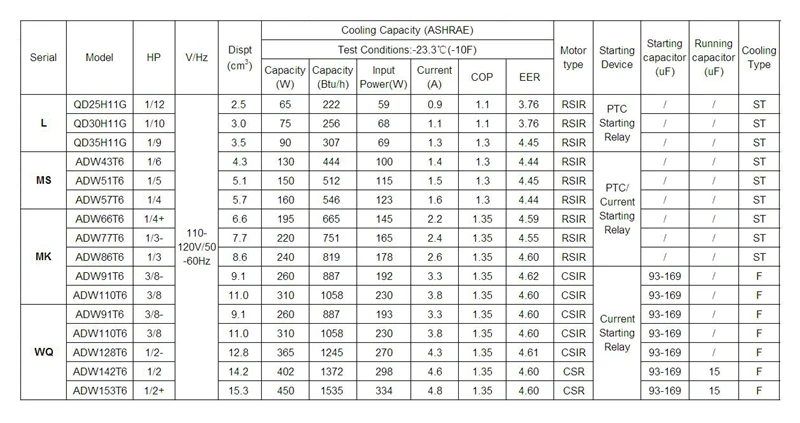

1.Product Performance

1)QD30H11G, L series, use R134a refrigerant;

2)Voltage application 110V to 120V;

3)Frequency for 50/60HZ;

4)Motor type: RSIR;

5)Cooling type: ST;

6)Starting device is PTC Relay;

7)Application: Low Back Pressure;

8)Nominal power is 1/10 HP;

9)COP is 1.1 with the cooling capacity 65W.

Basing on Test Condition(ASHRAE)

Evaporating Temperature: -23.3 degree

Ambient Temperature: 32.2 degree

Subcooling Temperature: 32.2 degree

Condensing Temperature: 54.4 degree

Suction Temperature: 32.2 degree

2. Compressor Dimensions

3.Compressor Specification

4.Compressor Packing and Container Loading

The vapor-compression uses a circulating liquid refrigerant as the medium which absorbs and removes heat from the space to be cooled and subsequently rejects that heat elsewhere. depicts a typical, single-stage vapor-compression system. All such systems have four components: a compressor, a condenser, a thermal expansion valve (also called a throttle valve or metering device), and an evaporator. Circulating refrigerant enters the compressor in the thermodynamic state known as a saturated vapor and is compressed to a higher pressure, resulting in a higher temperature as well. The hot, compressed vapor is then in the thermodynamic state known as a super-heated vapor and it is at a temperature and pressure at which it can be condensed with either cooling water or cooling air flowing across the coil or tubes. This is where the circulating refrigerant rejects heat from the system and the rejected heat is carried away by either the water or the air (whichever may be the case).

The condensed liquid refrigerant, in the thermodynamic state known as a saturated liquid, is next routed through an expansion valve where it undergoes an abrupt reduction in pressure. That pressure reduction results in the adiabatic flash evaporation of a part of the liquid refrigerant. The auto-refrigeration effect of the adiabatic flash evaporation lowers the temperature of the liquid and vapor refrigerant mixture to where it is colder than the temperature of the enclosed space to be refrigerated.

The cold mixture is then routed through the coil or tubes in the evaporator. A fan circulates the warm air in the enclosed space across the coil or tubes carrying the cold refrigerant liquid and vapor mixture. That warm air evaporates the liquid part of the cold refrigerant mixture. At the same time, the circulating air is cooled and thus lowers the temperature of the enclosed space to the desired temperature. The evaporator is where the circulating refrigerant absorbs and removes heat which is subsequently rejected in the condenser and transferred elsewhere by the water or air used in the condenser.

To complete the refrigeration cycle, the refrigerant vapor from the evaporator is again a saturated vapor and is routed back into the compressor.